The AcuTread® Process

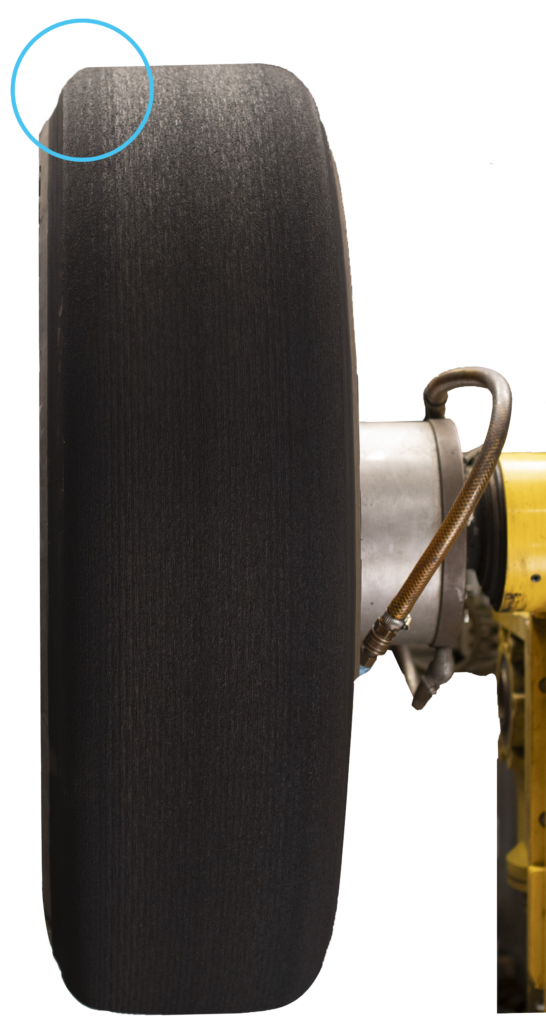

Professional Inspection

Trained technicians look for specific tire conditions that either qualify or disqualify the casings for retreading.

The casing is checked for micro-porosity and injuries; when detected, they are repaired using a 2-piece cured repair system.

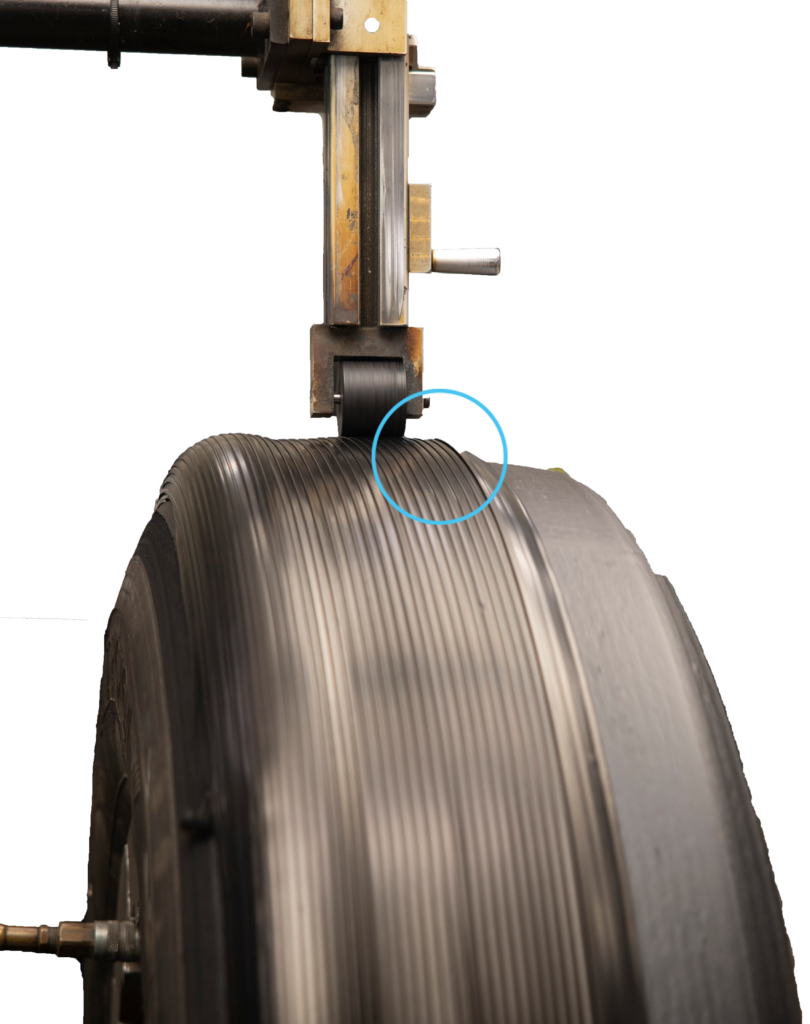

Cushion Extrusion

A thin layer of high-tack, uncured cushion rubber is applied to the buffed casing.

An exact specified width and depth automatically fills buzz-outs in the tread area.

This thin layer of rubber becomes the base for the extruded tread rubber, promoting tread-to-casing adhesion values that rival that of new tires.

Precision Rubber Application

Matched tire diameters result in even loading, a smooth ride, even wear, lower cost per mile and improved fuel efficiency.

AcuTread® mold curing uses high internal air pressure which results in superior adhesion values.

Final Inspection

After the molding and curing process there is a very thorough final inspection of the retreaded tire to ensure that the quality of the final product is at an unrivaled level.